October 28, 2025

A Complete Guide to Wood and Wood-Look Floors

by Annie Graybill

When it comes to transforming a room, few upgrades are as timeless and impactful as real wood flooring. In a world increasingly filled with plastic-based materials and synthetic alternatives, choosing natural hardwood brings warmth, integrity, and longevity to a space. Still, understanding the differences between the types of flooring available today can be dizzying. Here, we give you the history behind each and break down the pros and cons.

Solid Hardwood

Solid hardwood is what most people think of when they think of hardwood flooring. In reality, solid hardwood flooring was at its peak in the late 1800s through the mid-20th century.

Historically, solid hardwood planks were installed raw and then sanded, stained, and sealed on site. This allowed for a perfectly smooth and seamless surface, as the sanding could level out any minor irregularities between boards. This method is still widely used by contractors today.

The main drawbacks are the cost, mess, longer timelines, and the off-gassing of VOCs from stains and finishes. Today, there are some solid hardwood planks available that are prefinished, an option that is similar to engineered hardwood.

Pros:

- Beautiful, natural wood

- Highly customizable

- Can be sanded and refinished

Cons:

- High cost

- Messy, disruptive installation

- Long timelines

- Seasonal gapping between planks

- Commonly off-gas VOCs from stains and finishes

Engineered Hardwood

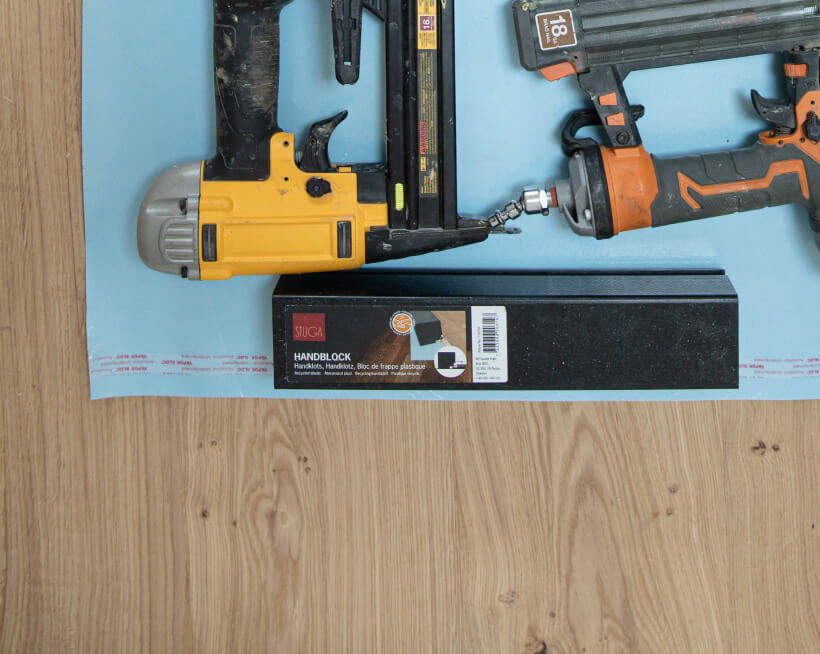

Engineered hardwood is a more sustainable option that was originally developed in Sweden in the 1940s. Now, it is very common in European homes and is gaining popularity in the US. It offers the same elegant look of solid hardwood but with added benefits.

Thanks to its layered construction, it handles humidity and temperature fluctuations more effectively. This makes it a smart choice for kitchens and basements. Engineered hardwood uses a slow-growing tree, like oak, as the top layer and faster-growing trees like pine and spruce for the other layers.

Outside of a handful of oiled options, Stuga floors are mostly prefinished with a matte acrylic coat. This protects the wood below without detracting from its beauty. The acrylic is cured with UV lighting quite quickly, resulting in an incredibly clear and hard finish. In contrast, the sand-and-finish process typical for solid hardwoods is typically less consistent, slower to cure, and leaves a strong smell from VOC off-gassing.

While engineered wood flooring can be sanded and refinished, the number of times depends on the thickness of the top layer. Most of our floors are sandable 2x, with the exception of the Rebels and Zig Zag. Sanding a floor is less common than you might think, and is best left as a last option when you want to change the stain color. If you simply want to give your floors new life, a buff and coat is a more affordable option and less messy than sanding.

Pros:

- Beautiful, natural wood

- Can be sanded and refinished

- Factory-applied finish

- Sustainable construction

- No seasonal gapping

- Easy to install

Cons:

- Medium to high cost

- Potential maintenance (oiled floors only)

- Potential for toxic glues and added formaldehyde (Stuga floors have no added formaldehyde, and our acrylic finishes are solvent-free)

Laminate

For those who love the look of wood but need a budget-friendly alternative, laminate flooring is another option made from high-density fiberboard (HDF), which consists of compressed wood fibers. It is not real wood. It is a photographic image layer that mimics wood, topped with a protective wear layer. Laminate is ideal for high-traffic areas, but it cannot be refinished once worn. Traditional laminate is not waterproof; moisture can cause swelling or warping. Some newer products are water-resistant but not fully waterproof.

Pros:

- Low cost

- Easy to install

Cons:

- Repetitive, printed faux wood grain

- Cannot be refinished

LVP

Luxury Vinyl Plank floors, or LVP, are 100% synthetic, usually PVC (vinyl). A printed image is layered with a protective wear coating, often textured to feel like wood. It is not real wood, is not sustainable, cannot be recycled or composted, and is horrible for the environment. The main ingredient in LVP flooring, PVC, is one of the most common plastics and the most environmentally destructive from its production to its disposal. There is no completely safe way to manufacture or dispose of PVC. In fact, the EPA is currently looking into banning vinyl chloride. With LVP, there are too many red flags to ignore.

Pros:

- Durability

- Low to medium cost

- Easy to install

Cons:

- Repetitive, printed faux wood grain

- Often high in VOCs

- Unsustainable from production to disposal

- Cannot be refinished

- Never biodegrades