April 25, 2025

Sawdust and Scenery: Notes From Our Trip to Sweden

by Haley Holm-Pedersen

Photography by Likeness Studio.

In the countryside of southwestern Sweden sits the small town of Nybro. You wouldn’t know it—there are no belching smokestacks in sight—but just off the city center is one of the oldest wood flooring factories in the world. Craftsmanship is treasured here, where skillful workers create flooring using the same techniques that many of their parents and grandparents used in this very factory.

Meanwhile, on the eastern coast, another wood flooring factory tells an entirely different story. Innovation is everywhere, from its incredibly efficient factory floor to its laboratories, constantly looking for new solutions to everyday problems.

Viken, a town on Sweden's eastern coast.

The first is the birthplace of the Icons, the OG wood floors from Sweden. These floors, like Greta, Fika, and Ingrid, have been made using the same construction since its invention in 1941. Not every Icon is made in Nybro; some come from Poland or Lithuania, but all are made with the same impeccable craftsmanship.

The second is where our wider Rebels, the anti-wood floor, wood floors, are made. Kickflip, Hang Ten, and Half Pipe (plus more to come) are produced at this Swedish factory. Their 6” counterparts, Giddy Up, High Five, and Cartwheel, are made in Croatia. In fact, the Croatian factory is located close to the forest where Rebels oaks are responsibly harvested.

In February, the Stuga team was lucky enough to visit both of these Swedish factories. Here’s what we learned along the way. Plus, a few recs for anyone traveling to southern Sweden or Copenhagen!

Day 1: Supplier Office Visit - Malmö, Sweden

The first night, we stayed in Malmö—a city in southern Sweden that’s a short train ride from bustling Copenhagen. A quick walk through the breezy February air and up the building’s artful spiral staircase landed us in our supplier’s office overlooking the ocean.

We immediately noted the warm wood floors everywhere, from heavy-traffic commercial spaces (like the Copenhagen airport security line!) to trendy restaurants. The offices had worn, old hardwoods that brought a layer of personality to a space often finished with cold tiles and gray carpets in the US.

Favorite things: Cardamom buns (Kardemummabullar). We couldn’t get enough of these! The subtle spice sets it apart from other baked goods.

Day 2: Supplier Factory Visit - Nybro, Sweden

A few hours by train, and we made it to Nybro for our first factory visit. A friendly yellow train station greeted us, and the sleepy town beyond was just as charming. We walked to the nearby factory and offices and kicked off the tour with a visit to a yard of massive oak logs. 75% of the logs milled at this site come from Swedish farms, and the rest are shipped in from other European countries. Each one is an average of 80 years old—youngsters in the context of European white oaks, who can grow for up to six centuries.

We moved on to tour the factory floor. The facility has been in operation since the 1800s, making wooden toys and other goods in the beginning. It’s believed to be the oldest continuously operating wood flooring factory in the world. But in true Swedish style, it’s also an environmentally conscious operation. From forest to end-of-life, every step is taken with intention. In the carbon-neutral factory, wasted wood is recycled into biofuel for the town of Nybro, heating homes and businesses in the winter.

To start, we watched massive band saws slice the oaks into smaller strips. Wood was then sorted depending on its size and character level. Some boards that might be perfect for Shell would be too rustic for Fika, for example.

Left: Band saw blades. Right: Logs are sorted by size and character.

Next, strips of pine are glued to a spruce backing, making a core that moves 25% less than solid oak. The top layer of oak is added to the newly formed core, and machines carve out a precise locking system on all sides. Workers check the locking system by hand—in fact, throughout the manufacturing process, every plank is checked 50 times by a human or computer.

Depending on the floor, different steps are taken to add finishing touches. Frida, for example, isn’t stained but is finished with an ultra-matte acrylic lacquer. The lacquer is applied in layers and hardened under UV lighting that dries very quickly, resulting in a super clear, hard finish. Brushes add a light texture to the finish, giving the floor a more natural look and feel. Shell, on the other hand, gets a different treatment. It’s stained to be a touch lighter than white oak’s natural color, then coated with an initial layer of oil for protection. Machines rout out wood around knots to bring them further to life, and handscraping details are added for additional character.

At the lab, floors are quality tested. Left: This test simulates dragging a sharp object over the floor with pressure. A result is recorded based on what it takes to reach raw wood. Right: A ball-drop test measures the impact of a steel ball dropped from several feet onto the floor.

Finally, the floors are packed up and ready to make their journey to the States. When we finished our tour, we moved on to reviewing rows and rows of floors that we don’t carry. We always do our best to balance the needs of our customers with a simple shopping experience, which is why we curate the selection of floors on our site to only the most versatile, design-friendly options our manufacturers offer. While we passed over many floors that didn’t fit our criteria, a few did pique our interest. Keep your eyes peeled in the next few months for new arrivals.

Since Nybro is a smaller town, we stayed in nearby Kalmar, a coastal city with more to see and do. After a long day of tours, we settled into the coziest seaside hotel for the night.

Favorite things: Elderflower everything! We fell in love with elderflower candies, lemonades, and cocktails. The light floral flavor is perfectly refreshing, and we found it everywhere in Sweden.

Day 3: Travel & Cultural Day - Kalmar, Sweden

On the third day, we set out to explore Kalmar and the surrounding areas before taking the three-hour train ride back to Malmö. Here are a few of our highlights from the day:

-

Kalmar slott, a castle that’s an easy walk from the city center. Its patinated copper roof, nearby swans, and gorgeous architecture were truly idyllic.

-

Nearby, a moose safari (!) offered an up-close view of the biggest animal in Sweden. Some of us brought kids along for this unique experience, and everyone had a great time.

-

The old town in Kalmar had several cafes and shops to explore, all paved with cobblestone streets.

Day 4: Supplier Office/Factory Visit 2 - Helsingborg, Sweden & Viken, Sweden

After settling back in Malmö, we hopped on another train up the coast in the opposite direction. This time, we were headed to see where the Rebels are born. Whereas the first tour tugged on our heartstrings with the craftsmanship involved in every step, this tour had an air of excitement about the flooring of the future.

Starting in the Helsingborg offices, we learned even more about the Rebels than we already knew. For example, the log below shows the thickness of typical cuts for solid wood flooring. By comparison, the Rebels can get 10,000 square feet out of the same log.

Since we launched them last year, the Rebels have been wildly successful (for good reason). The three colors and two widths that we offer right now are just scratching the surface of what’s available. We carefully considered new colors, formats, styles, and sizes, and will be bringing some into the fold in the coming months.

We set off to the factory in Viken, a small town further up the coast. The first thing that caught our attention was a large red container of wood pellets—just like the first factory, this one also recycles wood waste into pellets that are burned for energy.

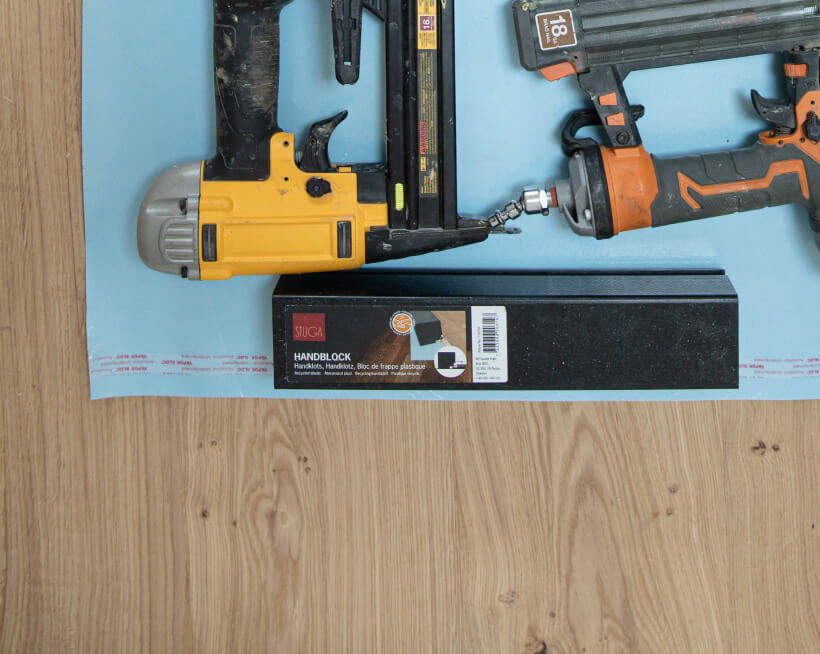

Bags of wood powder greeted us next, the perfect intro to one of the keys to the Rebels’ durability. This fine powder is compressed between the oak layer, core, and backing, reinforcing the strength of the wood on a cellular level. Seeing how fine it was in person, it was easy to imagine the powder working its way into the wood’s pores for an exceptionally tough product.

The wood powder that reinforces the Rebels.

We watched as the floors came together with efficiency and precision, largely executed by robots and machinery. Oaks were sliced with a knife-like blade rather than a saw for a cleaner cut and less sawdust. The slices were then glued together at their edges, creating large sheets that were then combined with the composite core, backing, and reinforcing wood powder.

The sheets were precisely cut into the planks that we know and love, and went through a finishing process similar to that of the first factory. Floors were stained (except for natural oaks like Hang Ten), then went onto get their water-based acrylic finish. Large brushes added texture to the grain, and again, UV technology was used to create a very clear and hard finish.

We moved on to the research and development area, where all kinds of testing were performed. Walking into one room felt like we were in the Everglades in July. The floors were being exposed to high heat and humidity to test their durability even in conditions far outside of the recommended levels. Another room featured a machine that emulated an office chair rolling over the floor thousands of times until bare wood was reached. Pools of water were left on the floors to see how long it would take for water to pass through the joint (which is officially watertight for 24 hours, but is being tested for longer periods).

Left: A variety of machines and tools are used to test the durability of the flooring. Right: A locking joint is examined for accuracy.

After a long and exciting day, we returned to Malmö for the night. In a city that dates back to the 1250s, we couldn’t resist visiting the historic Gamla staden, or ‘old town’ neighborhood, for dinner.

Favorite things: Our favorite spots to eat back in Malmö were Ruths—we’ve never had artichokes so delicious—and Årstiderna for an incredible, historic building and classic Swedish dining experience.

Day 5: Travel & Cultural Day - Copenhagen, Denmark

Our last day was spent exploring beautiful Copenhagen. Of course, one day is never enough, but here are a few highlights and recommendations from our day:

-

Designmuseum Danmark is a must! It’s located in the design district, so you can visit showrooms, vintage furniture shops, and more on your way. The building itself is stunning, and the museum, especially the Danish chair exhibit, is fascinating. With free lockers, strollers, and a great little cafe, it was also an easy and fun spot to take little ones.

-

Another one for the families; visit the LEGO store by Tivoli Gardens (LEGO is Danish if you didn’t know!) to create your own custom figurines. Just be sure to make an appointment, especially in busier seasons.

-

Rent a bike to experience the city like a local.

-

We went to Bæst for dinner after several recommendations. After rounds and rounds of beautiful appetizers, we hardly had an appetite for their signature pizza!

-

The Villa Copenhagen was the perfect hotel: right by the train station, beautiful rooms, and the best little bakery for breakfast.

Our whirlwind trip through Sweden was a blend of old-world charm and cutting-edge innovation. We saw firsthand the craftsmanship in Nybro and the forward-thinking spirit behind the Rebels in Viken. From sampling endless cardamom buns to marveling at moose, and even navigating Copenhagen's bustling bike lanes, it was an unforgettable adventure.

And if you happen to spot us hoarding elderflower candies, just know we're already planning our return. Skål!