March 20, 2024

How Stuga Stair Nosings Are Made

by Lauren Jones

When it comes to good design, we believe that quality should extend not just on the floors but to the stairs as well.

Have a full-home renovation coming up or just looking to enhance your builder-grade stairs? Our stair nosings are the perfect solution for a custom look and ship right to your door.

We sat down with Ivan, our stair nosings expert, who handcrafts each nosing at our sample shop in Austin, Texas.

How did you start working with Stuga?

I met Marc as soon as he moved to Texas around 2018. He had worked with another woodworker when he had his business, Scandinavian Hardwoods, in Colorado and was already putting out nosings. I had never done stair nosings before but was confident I could given my background in architectural millwork.

Tell us more about your background.

When I moved to Austin in 1994 when I was 20, I started working in a woodshop. I had some construction experience at the time. The woodshop owner was the original butcher for the first Whole Foods so many projects we did were helping to build, design, and do commercial millwork for the stores. I’ve probably designed 100 Whole Foods stores by now. I built mostly high-end custom store fixtures and during that time learned AutoCAD and how to program a CNC machine all before I even owned a computer.

My background in woodwork and manufacturing processes helped me understand the process of building stair nosings.

How do you make the stair nosings?

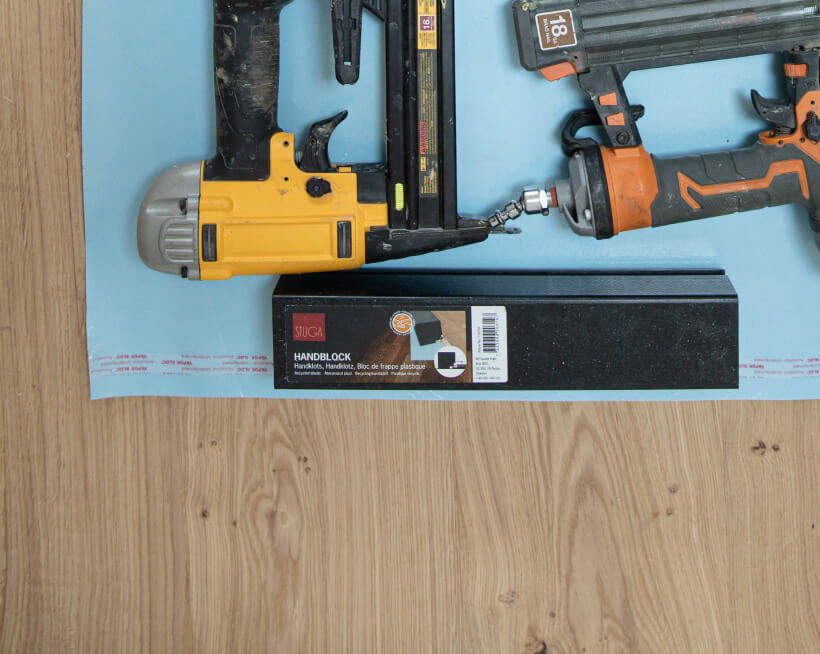

We have a CNC machine on-site. It’s a digital manufacturing tool that allows us to create the same product the exact same way to specific standards every time. Before the CNC machine, I was cutting them by-hand, but with the CNC machine I can produce a more consistent product.

How long do stair nosings take to make?

The actual hands-on time for stair nosings from start-to-finish with dry time is four hours per nosing. I do them in batches so I can do say 50 of them in 10 hours.

First, I cut a batch. I can cut about 50 in five hours and there's some prep time with getting the order ready and all the boards in. I sand the edges and clean up the glue and leave them to cure for 24 hours.

Which floor is your favorite to make stair nosings out of?

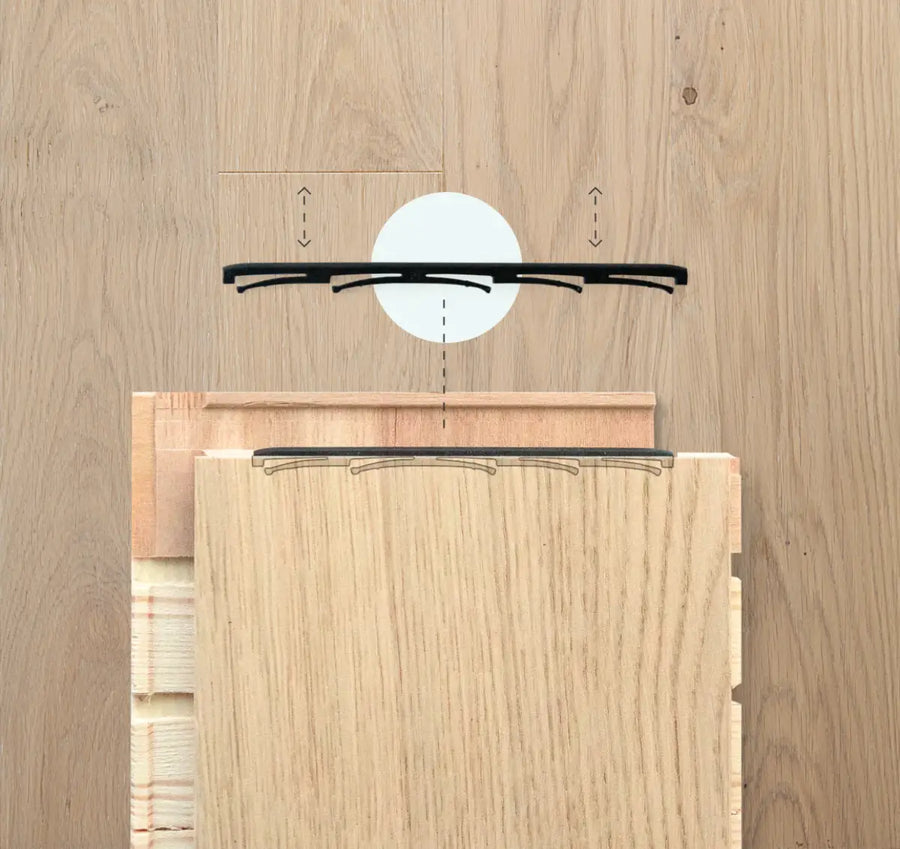

What’s the difference between a square nosing and flush nosing?

The nosings have a slightly different construction. With flush nosings, I don’t use nails, but with the square nosings I use micro pins and nails on the bottom, so there are no visible fasteners. Custom flush with edge caps are a bit trickier.

Does the wood glue you use have added formaldehyde?

No, it’s formaldehyde-free. I use Titebond II, a water-resistant wood glue. It can also hold up to more than 3,000 pounds per square inch. We actually put a nosing on the table at the sample shop and hit it with the hammer to test. The wood broke before the glued pieces did.